Industrial Monitor

AI-driven geospatial analytics tracks machinery, materials, and movements across factory sites, providing real-time operational, security, and compliance insights.

AI-driven geospatial analytics tracks machinery, materials, and movements across factory sites, providing real-time operational, security, and compliance insights.

How does it work?

Many factories rely on manual inspections and siloed sensors, delaying detection of inefficiencies, unauthorized activities, and safety hazards. Geospatial AI centralizes overhead imagery and data feeds to deliver timely, comprehensive site activity monitoring, enabling proactive decisions.

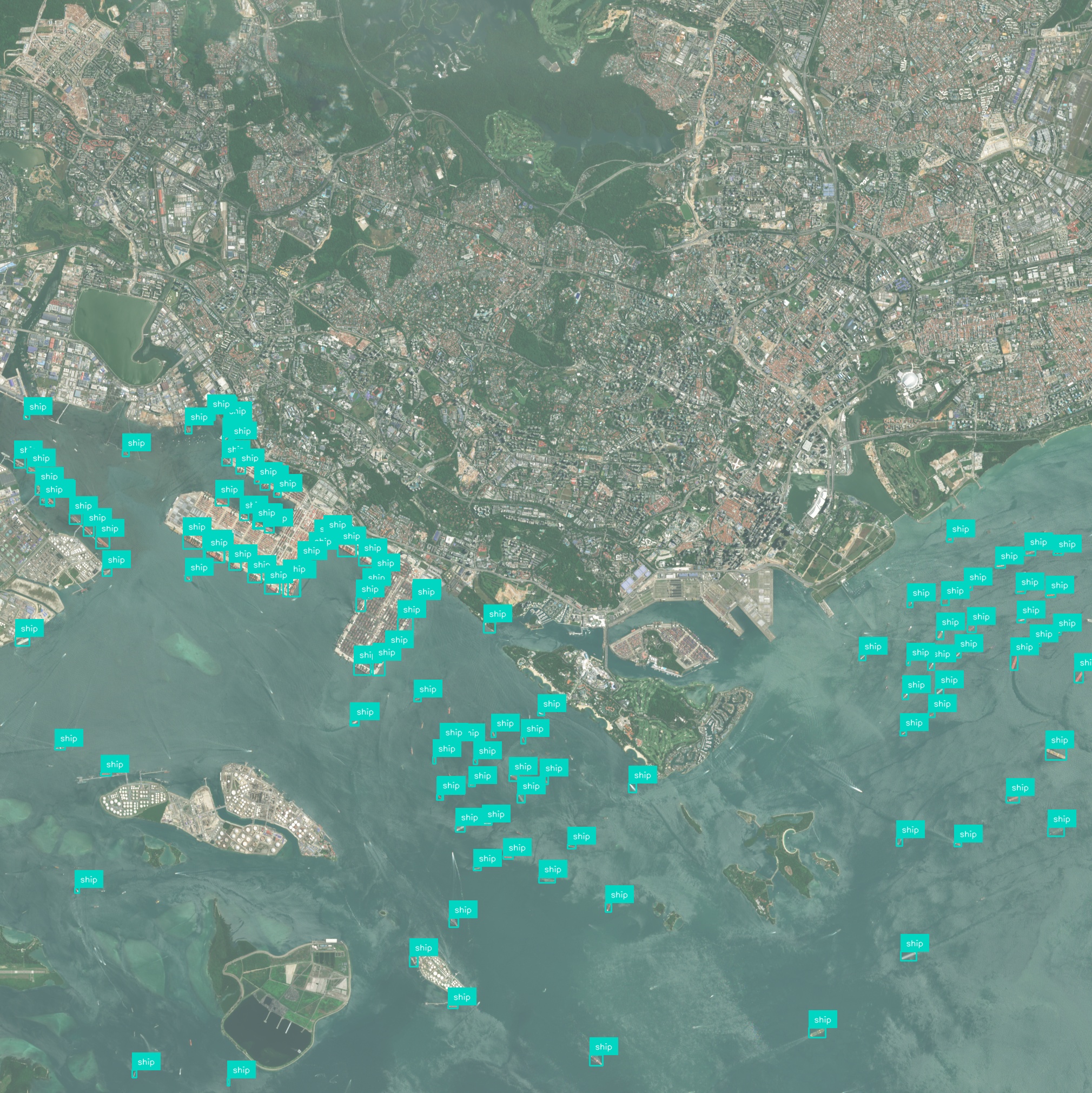

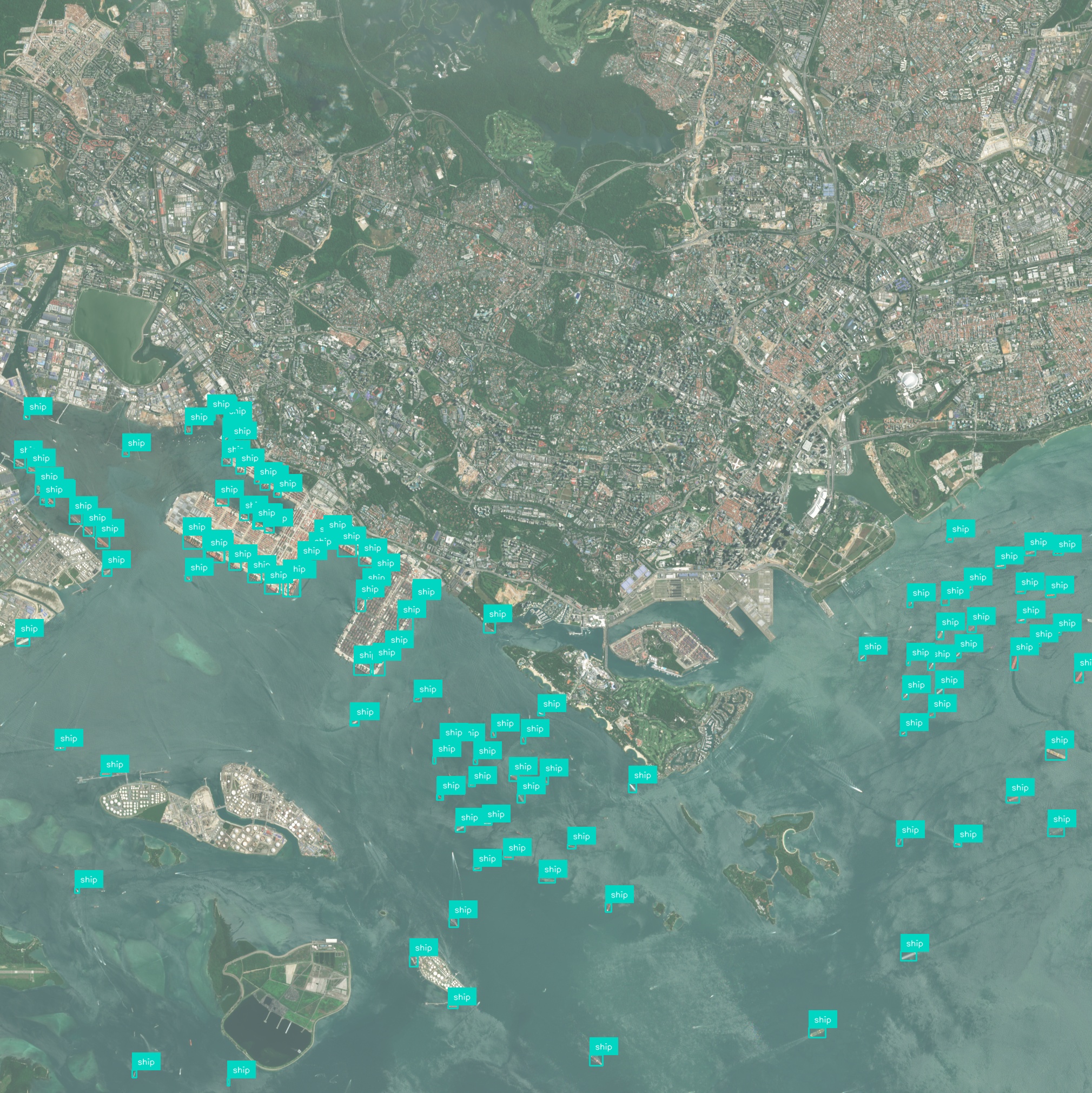

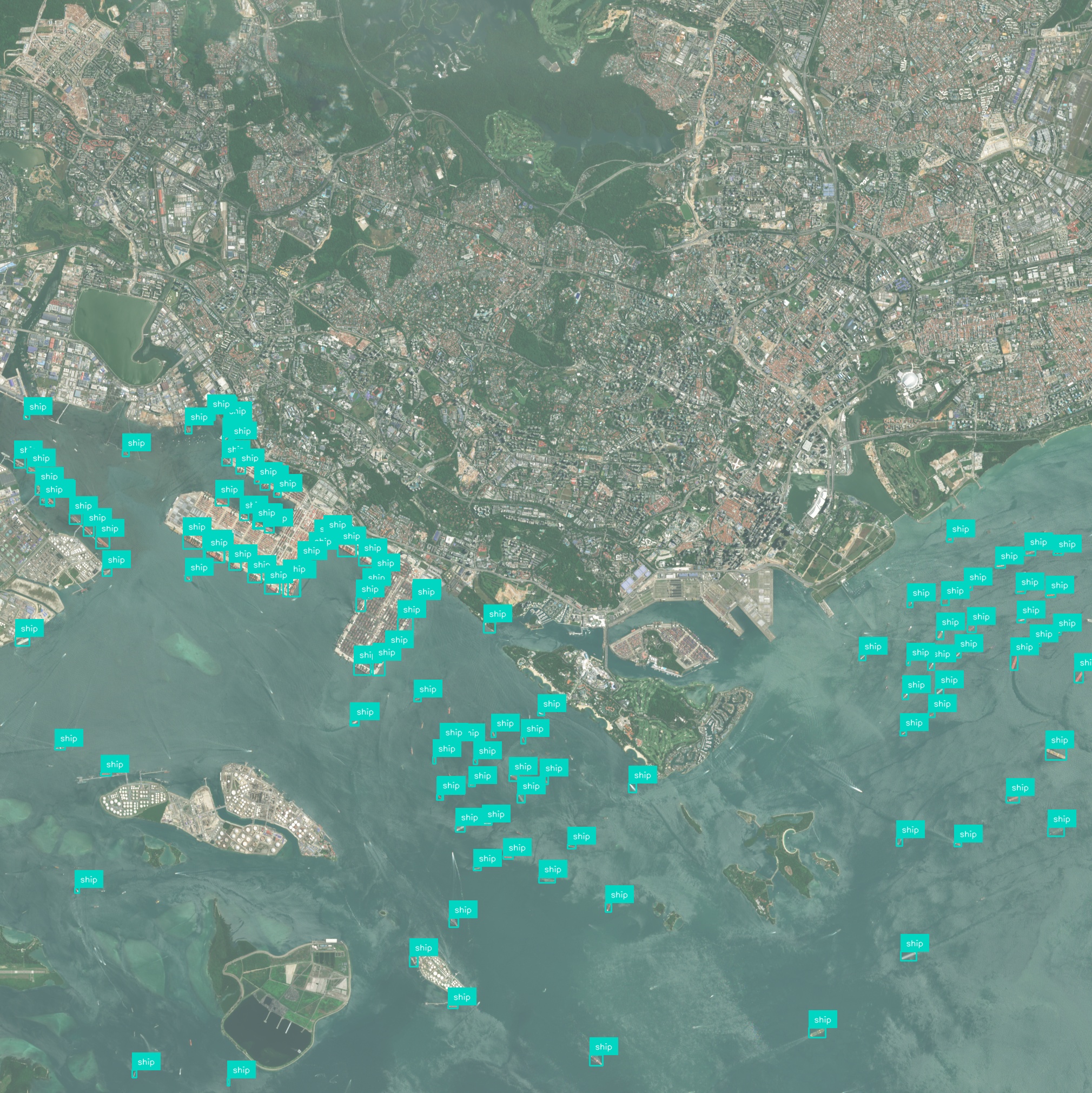

Continuous analysis of satellite and drone imagery reveals machinery movements and material handling as they happen. This immediate visibility helps managers identify bottlenecks and unauthorized access without manual checks.

Geospatial analytics quantifies equipment locations, usage patterns, and idle times across the site. These insights inform resource allocation, reducing downtime by up to 20%.

Automated monitoring flags unsafe conditions such as unauthorized zone entries, chemical spill risks, and perimeter breaches. Reports and visual dashboards support regulatory audits and internal safety protocols.

Spatial trend analysis highlights process throughput, workflow hotspots, and layout inefficiencies. Data-driven adjustments to plant layouts and schedules optimize production flow.

High-resolution imagery tracks emissions, dust plumes, and waste storage compliance in real time. Early detection of leaks or non-compliance zones minimizes environmental fines and cleanup costs.

AI models detect deviations from normal activity patterns and send instant notifications for suspicious events. Cloud-based workflows integrate these alerts with existing incident management systems for rapid response.

Have a different question and can’t find the answer you’re looking for? Reach out to our support team by sending us an email and we’ll get back to you as soon as we can.

Geospatial AI Platform

AI & foundation models

Deep-learning and foundation models turn raw imagery into ready-to-use insights, so you ship answers instead of training pipelines.

Conversational workflow

Ask questions in plain language and the platform responds with charts, visualizations, and next step suggestions.

GPU-accelerated cloud

Cloud-native architecture spins up on-demand GPU clusters that scale from a single scene to global archives—no manual ops, no bottlenecks.

Any sensor, any format

Optical, SAR, drone, IoT, vector or raster—ingest, fuse, and analyze without conversion headaches.

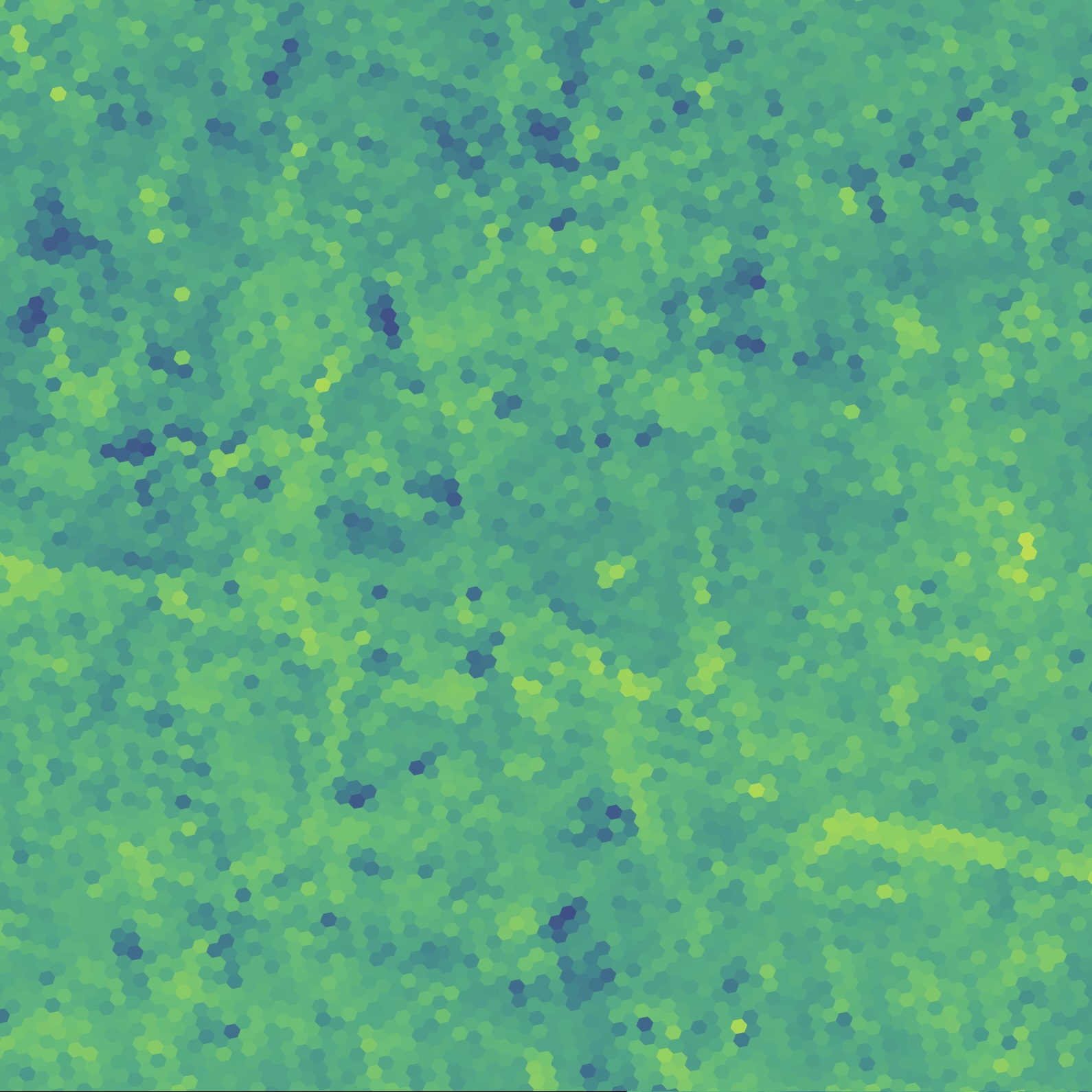

Insight you can see

Real-time 2D / 3D maps and export-ready plots make results clear for engineers, execs, and clients alike.

Turn satellite, drone, and sensor data into clear, real-time insights using powerful AI – no complex setup, just answers you can see and act on.