Blade Defect Scan

Autonomous drones armed with X-ray and SAR imaging generate digital twins of turbine blades for defect detection and lifetime prediction.

Autonomous drones armed with X-ray and SAR imaging generate digital twins of turbine blades for defect detection and lifetime prediction.

How does it work?

Traditional blade inspections rely on manual visual checks that can miss subsurface defects and incur high operational costs. Integrating autonomous drones with X-ray and SAR imaging enables comprehensive non-destructive evaluation and feeds digital-twin analytics for accurate lifetime predictions.

X-ray and SAR imaging reveal hidden cracks and voids below the blade surface. Early detection prevents minor flaws from evolving into critical failures.

Autonomous drones conduct inspections without manual intervention, reducing downtime and safety risks. Scheduled flights ensure consistent monitoring across the turbine fleet.

Combined X-ray and SAR data produce detailed 3D damage maps. Maintenance teams can pinpoint defect locations with centimeter-level accuracy.

Digital twin models ingest imaging data to simulate blade performance under operational loads. Predictive analytics forecast remaining service life and optimize maintenance schedules.

Precise defect identification minimizes unnecessary repairs and blade replacements. Proactive maintenance extends blade lifespans, lowering overall operational expenses.

The platform supports large-scale turbine fleets with cloud-based processing and data management. Automated workflows streamline inspection, analysis, and reporting across multiple sites.

Have a different question and can’t find the answer you’re looking for? Reach out to our support team by sending us an email and we’ll get back to you as soon as we can.

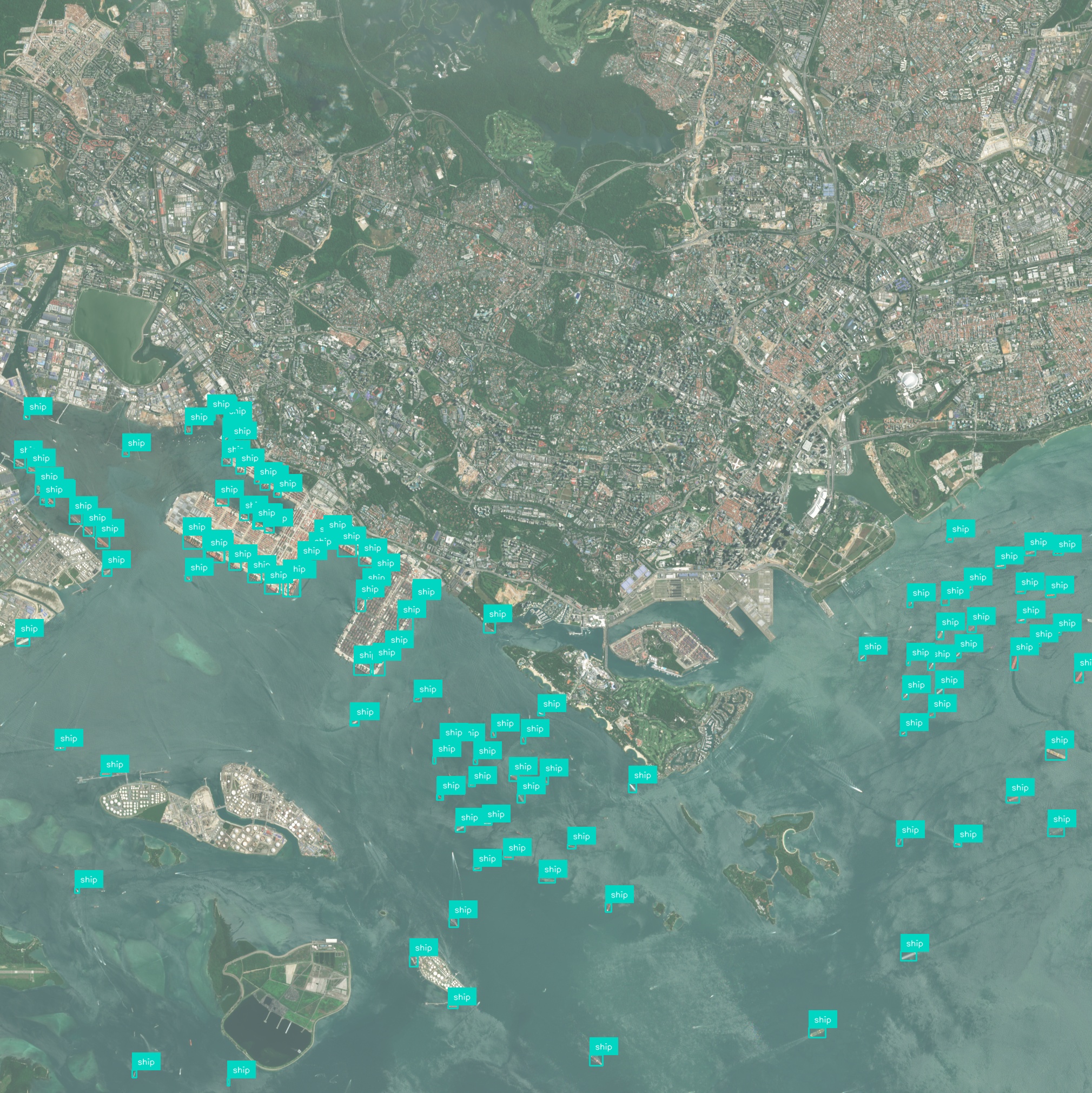

Geospatial AI Platform

AI & foundation models

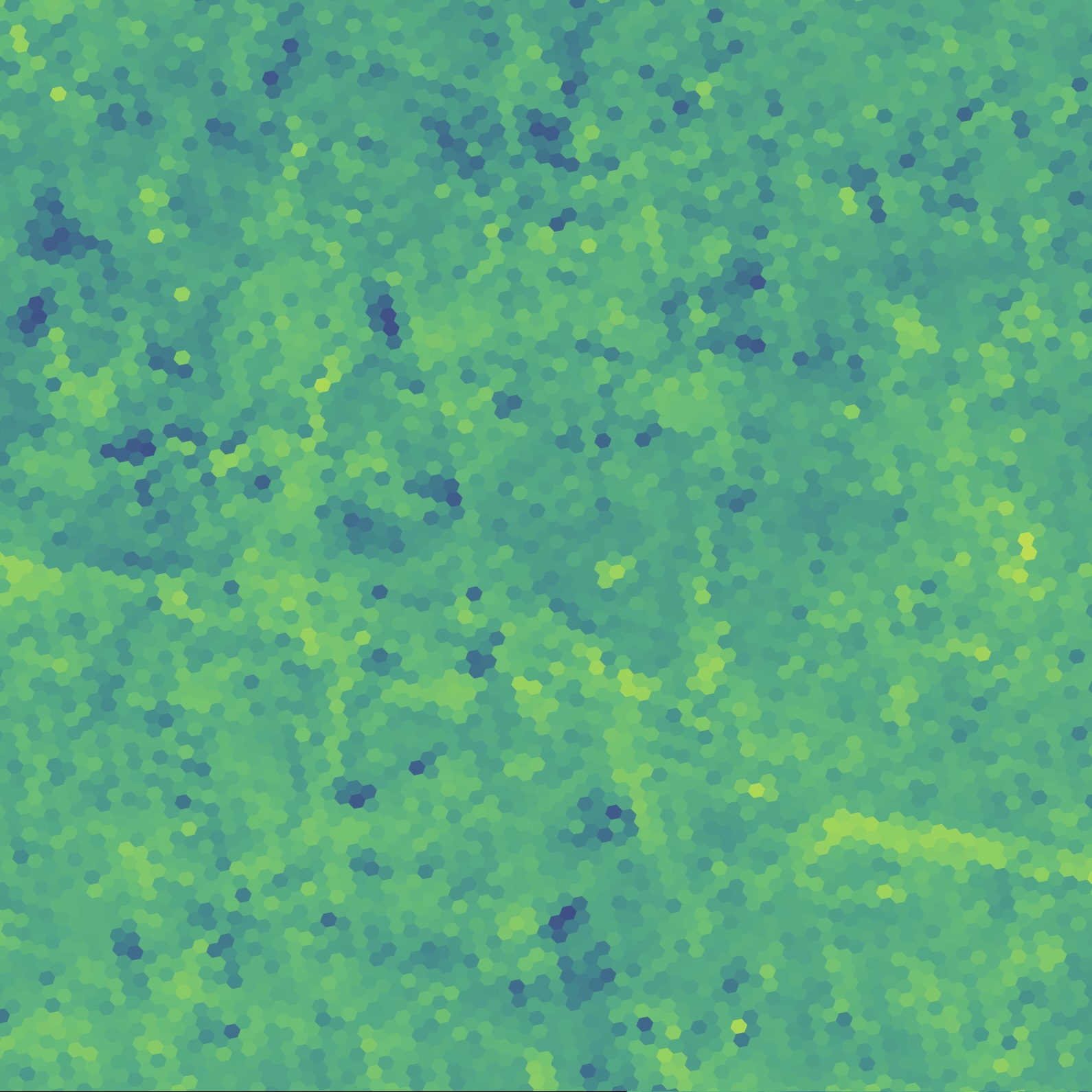

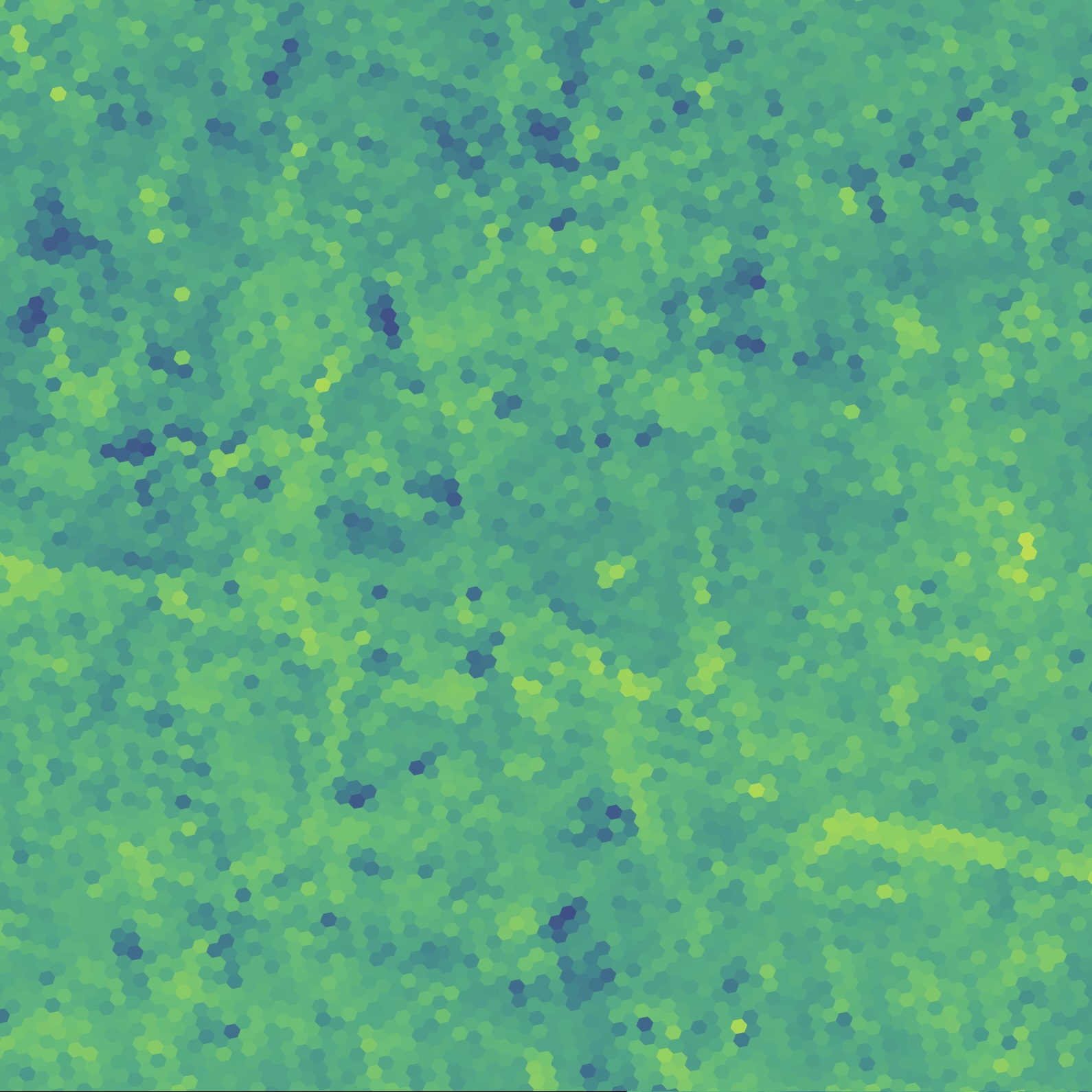

Deep-learning and foundation models turn raw imagery into ready-to-use insights, so you ship answers instead of training pipelines.

Conversational workflow

Ask questions in plain language and the platform responds with charts, visualizations, and next step suggestions.

GPU-accelerated cloud

Cloud-native architecture spins up on-demand GPU clusters that scale from a single scene to global archives—no manual ops, no bottlenecks.

Any sensor, any format

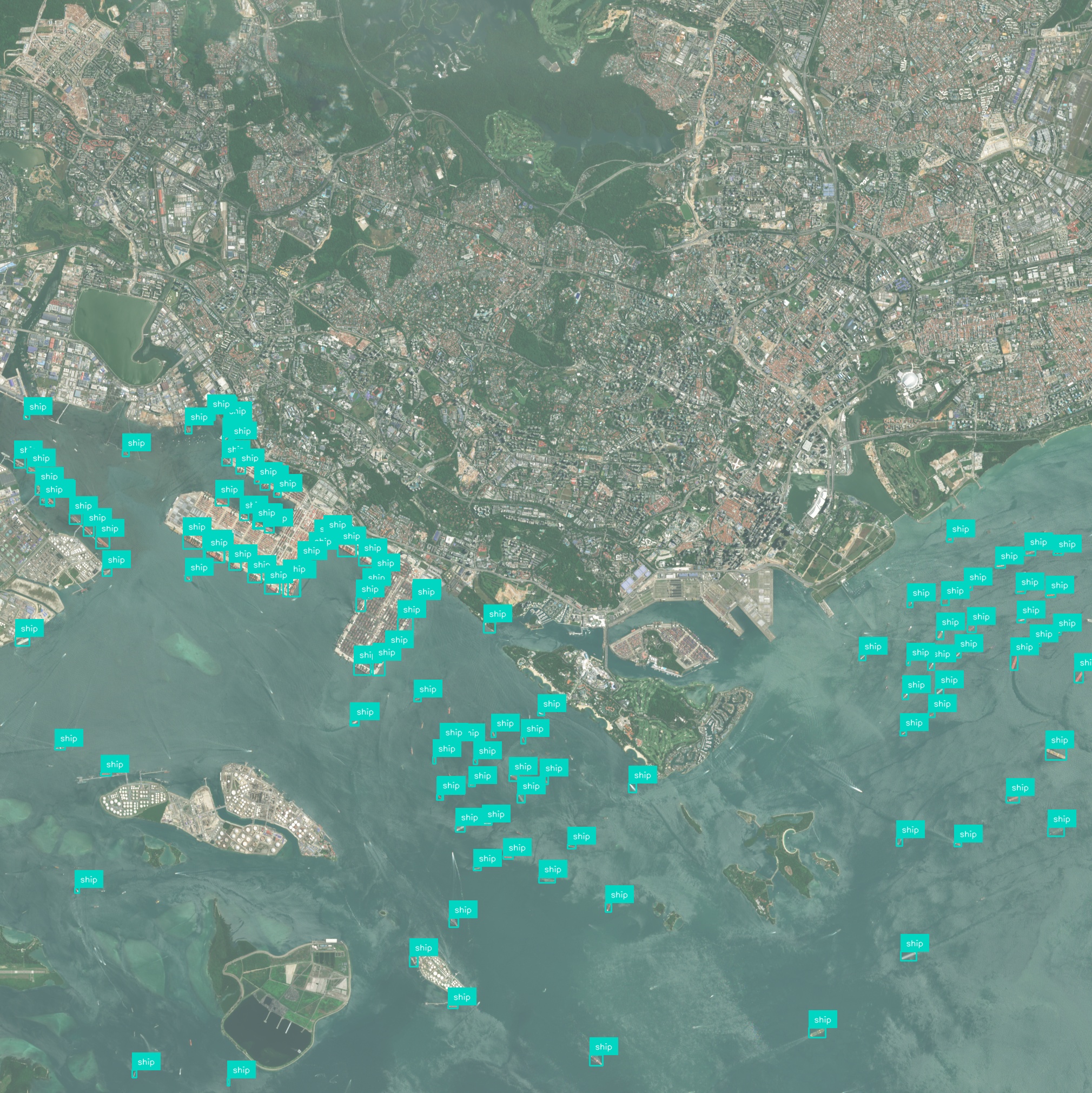

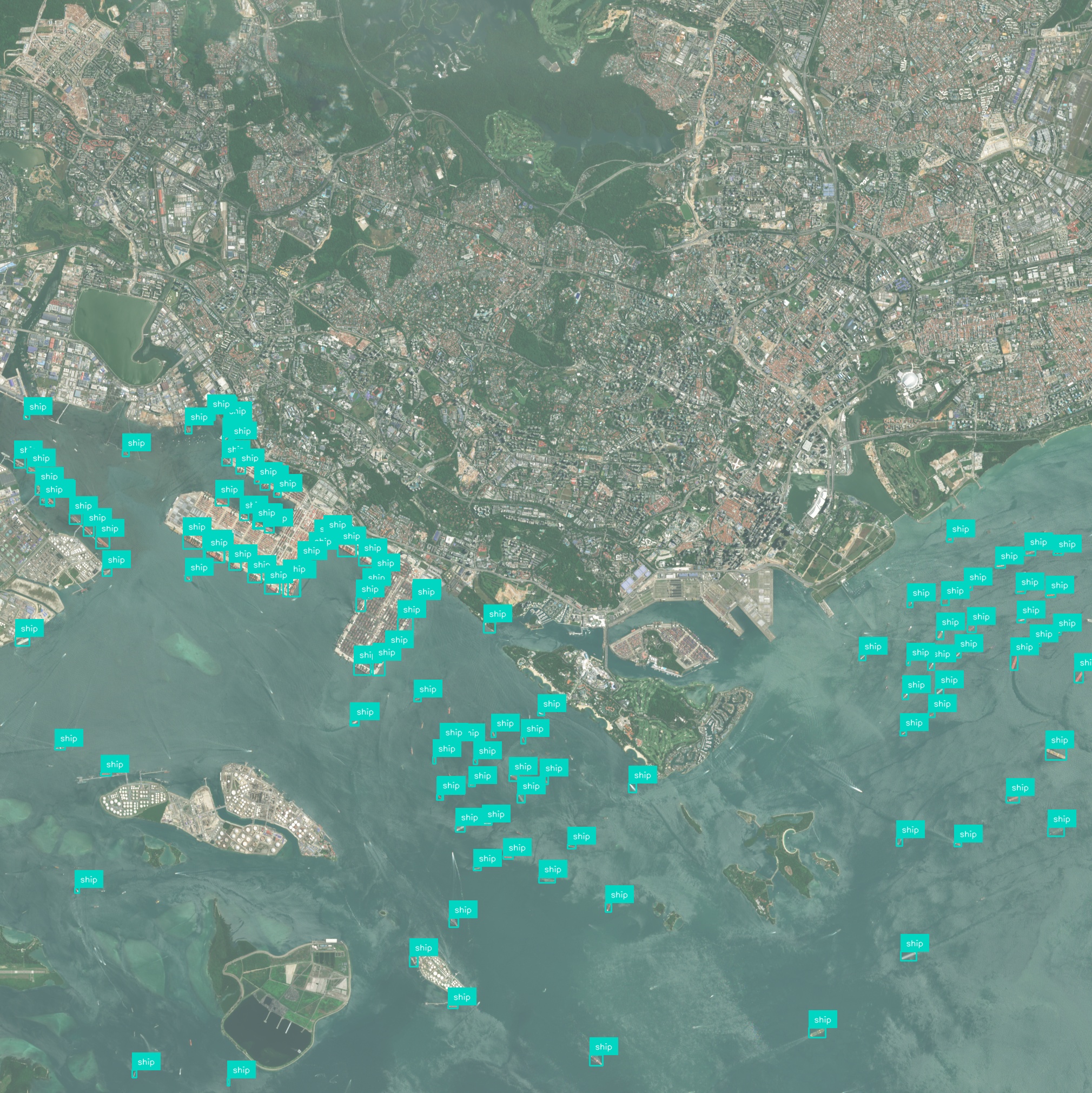

Optical, SAR, drone, IoT, vector or raster—ingest, fuse, and analyze without conversion headaches.

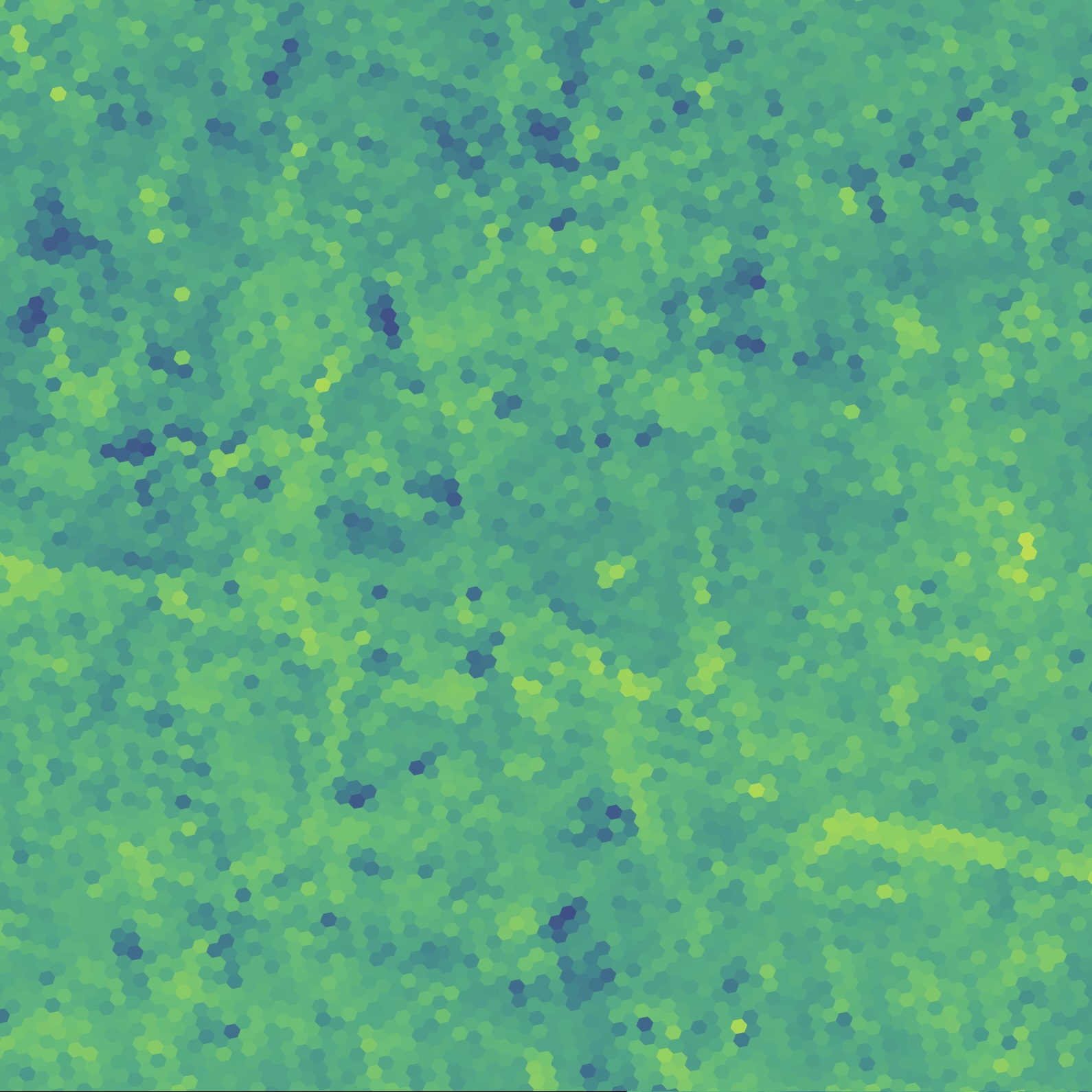

Insight you can see

Real-time 2D / 3D maps and export-ready plots make results clear for engineers, execs, and clients alike.

Turn satellite, drone, and sensor data into clear, real-time insights using powerful AI – no complex setup, just answers you can see and act on.